Wood Plastic Composite Decking, WPC Solid Decking, 150 X 30 mm

Description Of High Quality Wood-Plastic Composite Decking from China Product Application Of Composite Decking SWIMMING

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | KS150S30B |

| Certification | CE |

| Usage | Outdoor |

| Customized | Customized |

| Material | 65% Wood Fiber+30% HDPE+5% Addictives |

| Certificates | ISO/Ce |

| Length | 2.2/2.9/3.6/5.8meter |

| Installation | Easier to Install |

| Advantages | Waterproof |

| Transport Package | Using The High Quality Carton or Pallets |

| Specification | 150mm*30mm |

| Trademark | Kelai |

| Origin | China |

| HS Code | 3918909000 |

| Production Capacity | 15000 Ton/Year |

Product Description

Description Of High Quality Wood-Plastic Composite Decking from China| Products Name: | WPC DECKING, WPC FLOOR, WOOD PLASTIC COMPOSITE,WOOD PLASTIC Ani-UV Waterproof Composite Floor Decking For Gargen,Small Groove WPC decking, Flat sanding WPC decking |

| Brand: | Kelai |

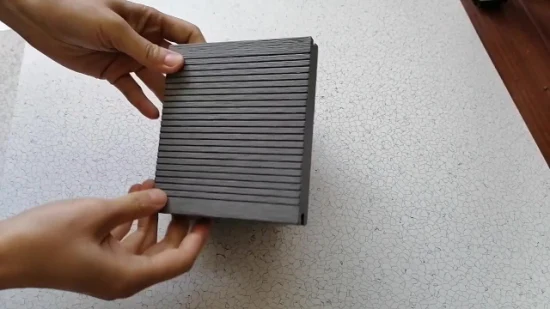

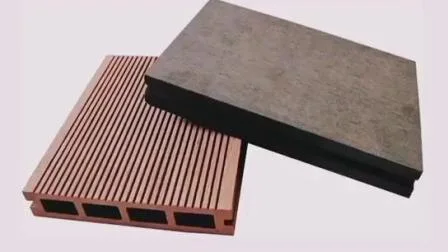

| Size: | 150*30mm |

| Length: | 2.2 or 2.9 and 3.6 meters. Sizes can be according to the client requirements. |

| Color: | Black, Gray, Olive Green, Red Wood, Coffee, Wood |

| Surface: | Smooth, Brushed, Scratched, Grain & Sanded, 3D embossing, Deep Wood Grain |

| Component: | 30%-35%HDPE,60%-65%wood powder and 10%chemical additives |

| Material Introduction | WPC ( Wood Plastic Composites), a new kind of composite material.Plastic and wood powder are mixed according to above proportion after hot extrusion molding plate. |

| Applications: | Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground. |

| Certificate: | ISO.9001/ISO.14001/CE |

| Appearance: | Looks and feels like natural wood. |

| Advantage: | 1,Composite decking is excellent color fastness. 2,Good surface hardness of Composite decking. 3,It is easy for cleaning and free maintenance for composite decking 4,More protection due to the outmost co-extrusion layer. 5,Material of composite decking is eco materials and recycled. 6,there is natural appearance of composite decking. 7,Composite decking is insect resistance. 8,Composite decking is already popular in USA and Europe for years |

| Composite Decking Particularity: | High degree of UV and color stability. |

| Cost for installing composite Decking: | Easy to install and clean ,low labor cost. |

| Maintenance: | Requires no painting, no glue, low maintenance. |

| Recycling: | 100% recycle, environmental friendly, saving forest resources. |

| Environmental friendly: | Barefoot friendly, anti-slip, no cracking. |

| Low/High Temperature resistance: | Weather resistant, suitable from -40°to 60°. |

Product Application Of Composite Decking

SWIMMING POOL YARDS GARDEN GAZEBO

Outdoor Scene of WPC Decking

Standard Color

How to Pack WPC Decking Installation Instructions of WPC Decking

FAQ

1. What is the main ingredient of your WPC?

It is made from 60% recycled wood fiber, 30% recycled HDPE and 10% additives, like pigment, anti-UV agent, anti-oxidant, etc.

2. What is wood species of wood fiber you use?

Eucalyptus, poplar and some mixed wood, which is color related.

3. What about the temperature range of your WPC can be used?

-40 to 60 degrees.

4. What about the warranty of your WPC?

15 years warranty. Letter of warranty can be sent.

5. Will your WPC have color fading?

To be honest, our WPC will have some color fading during the first 6 months after installation, but not obivious.

6. What about your main market?

Our focus is always oversea market. More than 90% of our products are for export, and our main market is Greece, Czech Republic, Italy, Germany, Spain, Austria, Swiss, Estonia, Norway, UK, Korea, Thailand, Indonesia, Vietnam, USA, Canada, Argentina, Australia, etc.

7. What is the advantage of solid decking compared to hollow decking?

Less easier to crack. Higher tensile strength. Less distortion with load-bearing. Lower water absorption rate. Joist span can be comparatively bigger.

8. What is the material of your co-extrusion WPC?

Shield layer (protection layer): engineered plastic. Core: wood plastic composite.

9. Can we say co-extrusion WPC is better than normal WPC?

We can not simply say which one is better. Different customers have different likes. For co-extrusion WPC, it will not have color fading problem, more anti-scratch, and more stain resistant.

10. What properties will you test for your raw material and end products? Wood fiber: ash content, fiber size, water content.

HDPE: melting index, ash content, physical property test for finish product

End product: strength test, boiling test and expansion rate test, temperature cycle test, outdoor UV test

11. How many production lines you have? What about the production capacity per month?

14 extrusions lines. 30-35 containers per month.

12. How many sqm. of decking can be loaded in 1x20GP container?

Appr. 800 sqm. of decking, plus joist and accessories.

13. What about delivery time for one container?

15-20 days upon deposit payment well received.

14.What kind of certification you have?

ISO9001, ISO14001, FSC certification. As for test report, there is test report done according to EN15534 standard and ASTM standard.

15. Have you ever received any complaints from your customers?

Frankly speaking, yes. And it's mainly about color difference, cause our raw material is recycled material, there is always difference between different lots. Now mixing is done for our HDPE plastic and also after pelletizing to well control of this problem.

Related Products

-

![Jumei Factory Wholesale 3mm 5mm 4X8FT Size Outdoor Signs Displays Kitchen Cabinet Wall Panel White Flexible Plastic Expanded Celuca Forex Sheet PVC Foam Board]()

Jumei Factory Wholesale 3mm 5mm 4X8FT Size Outdoor Signs Displays Kitchen Cabinet Wall Panel White Flexible Plastic Expanded Celuca Forex Sheet PVC Foam Board

-

![Hot Sales & Cheap WPC Decking with CE, FSC, ISO9001, ISO14001]()

Hot Sales & Cheap WPC Decking with CE, FSC, ISO9001, ISO14001

-

![Waterproof Plafond Lambris PVC Suspended Tubular False Ceiling Linning Panel 6m]()

Waterproof Plafond Lambris PVC Suspended Tubular False Ceiling Linning Panel 6m

-

![Modern Large Metal Planter Pot Long Outdoor Flower Pot Rectangular Planter Box]()

Modern Large Metal Planter Pot Long Outdoor Flower Pot Rectangular Planter Box